Ducted Wet Dust Collector

From 500 CFM to 30,000 CFM

The Uni-wash series stands out as the market's most efficient wet dust collector, capable of capturing dust particles as small as 3 microns with just 3" of water column static pressure.

Wet dust collection is vital for safely gathering combustible metal dust (NFPA 484), and it has proven effective in various challenging environments, including food processing and pharmaceuticals, as an alternative to cartridge collectors. Our scrub design, a longstanding industry standard for over 50 years, remains at the forefront of wet dust collection efficiency.

Specifications

≤

3,000 CFM

NFPA 484 Compliant

With Industry Leading AccuScrub Controls

Uni-Wash wet dust collectors meet NFPA 484 standards for capturing combustible metal dusts from processes involving aluminum, magnesium, titanium, and zirconium (when paired with the AccuScrub Control Panel).

If your process involves these materials, Uni-Wash collectors significantly reduce fire and explosion risks, ensuring worker safety and compliance. They are self-contained with minimal water usage after initial fill and boast straightforward installation and start-up.

Low-Cost Operation

Using water as a filtration medium offers advantages. Dust collects as sludge in the sump, facilitating easy removal or drainage. With no disposable filters to replace, costs are reduced, and airborne contamination risks minimized. Additionally, our scrub design reduces the machine's static pressure requirement, resulting in lower horsepower needs, thus reducing both initial and lifetime energy costs.

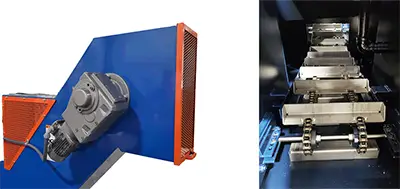

High Efficiency Motors

Booths operate at a lower static pressure, only requiring pressure for scrubbing, eliminating the need for scrolled fans. Instead, we use plug fans, reducing machine costs. Additionally, high-efficiency direct-drive motors lower operating costs throughout the equipment's lifespan.

ProVent, A Name You Can Trust

The Uni-Wash wet dust collector, in production for over 50 years, remains a leading technology for capturing dust without cloth filter media, originally designed for combustible metal dust collection. Manufacturers have since applied this successful technology to various challenging applications.

Orifice / Impingement Scrub

The patented scrub cone assembly, with its large diameter, operates above the water line. Unlike submerged internal venturi designs prone to clogging and airflow reduction over time, this orifice/impingement design remains clear. With Uni-Wash, there are no pumps or spray nozzles to clog or malfunction.

Uni-Wash UC Popular Options

Performance upgrades for additional static pressure when needed for long duct runs or the use of after-filters.

A single strand or double strand sludge conveyor will remove collected dust from the bottom of the tank. Typically used in heavy loading processes.

Stainless steel construction is an option on all ProVent products. Uni-Wash products have an option for the tank (bottom half of collector) to be stainless steel and the upper housing to be mild steel.

An immersion heater can be installed for wet collectors that will be installed outside where the temperature may be below freezing.

Adding a silencer will decrease the noise emitted via the exhaust air 7-9 decibels.

We offer four control options for all Uni-Wash products. We are a UL 508A certified panel shop and all panels are manufactured to work seamlessly with our dust collectors.

Base Control Options

Low-cost options where advanced features are not needed. These are an excellent option for down draft benches and booth collectors.- Across the Line Motor Starter

- Not NFPA 484 Compliant

- NEMA 3R/4/12 Plastic Enclosure

- Float Water Level Control

- Sludge Conveyor Operation via VFD

- Motor Control via Rotary Knob

- Combination Motor Control

- Not NFPA 484 Compliant

- NEMA 3R/4/12 Enclosure

- Float Water Level Control

- Face Mounted Rotary Disconnect

- E-Stop

- 110 Volt AC Components

- Indicator Lights for motor status

- Remote Start / Stop Optional

- Sludge Conveyor Operation via VFD

Our feature rich control panel with touchscreen controls.

Our feature rich control panel with touchscreen controls.

- Fully NFPA 484 Compliant

- NEMA 3R/4/12 Enclosure

- 7-inch Touchscreen

- Provides visual real-time data, control of dust collector and optional components (Auto drain-refill, fault acknowledgement and reset)

- Ultrasonic Water Level Control

- Face Mounted Rotary Disconnect

- E-Stop

- 24 Volt DC Components

- Process Interlock

- Connects power supply to the dust collector to the dust producing equipment

- Stack Light with Audible and Visual Alarms

- Remote Start / Stop Optional

- Sludge Conveyor Operation via VFD

ProVent's premier control panel for Uni-Wash products. The AccuScrub PRO provides optimum efficiency and an easy-to-use 10-inch touchscreen control.

ProVent's premier control panel for Uni-Wash products. The AccuScrub PRO provides optimum efficiency and an easy-to-use 10-inch touchscreen control.

- Fully NFPA 484 Compliant

- NEMA 3R/4/12 Enclosure

- 10-inch Touchscreen

- Provides visual real-time data, control of dust collector and optional components (Auto drain-refill, sludge conveyor, fault acknowledgement and reset)

- Ultrasonic Water Level Control

- Face Mounted Rotary Disconnect

- E-Stop

- 24 Volt DC Components

- Process Interlock

- Connects power supply to the dust collector to the dust producing equipment

- Stack Light with Audible and Visual Alarms

- Remote Start / Stop Ready

- Variable Frequency Drive (VFD)

- Provides manual or automatic control of fan RPM to ensure optimal scrub pressure at maximum efficiency.

CONTACT US - We will be happy to answer all of your questions!