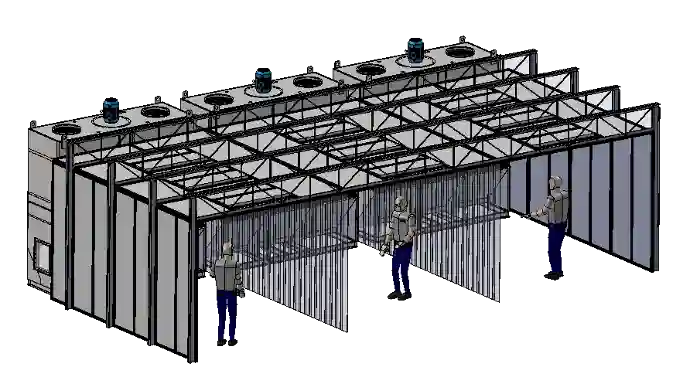

Environmental Work Cell

Each

Intercept™

EWC Series Environmental Work Cell is a self-contained,

modular cartridge dust collection system.

Sizes range from 4,000 – 16,000 CFM.

Designed to accommodate booth enclosures of various sizes, EWCs are used

in singular or multiple-unit configurations to solve dust containment

challenges for large-area applications where source capture is not

practical. The work area is continuously cleaned by MERV-15 cartridge

filters with filtration capabilities of 99% efficiency down to 0.5 micron. Cleaned

air is exhausted back into the plant environment. Booth enclosures are custom designed to meet

process requirements. The EWC features

internal reverse pulse filter cleaning assemblies, with nested diaphragm valves

and compressed air manifolds. The light-weight, torturous-path aluminum louvered front inlet panels are easily removed for full access to the filter chamber. Dust is captured in the slide-out drawers

below.

Features

This system is designed with ease-of-use in mind, ensuring that dust collection is as straightforward and efficient as possible for industrial environments. Each component is built for quick access, fast maintenance, and reliable performance, keeping the workspace safe and clean with minimal effort.

Removable Aluminum Louvered Intake Panels for Easy Filter Changes

The intake panels are constructed from durable aluminum, designed with louvers to optimize airflow while preventing larger particles from entering the system. These panels are easily removable, making routine filter changes quick and convenient, reducing downtime for maintenance. This feature ensures the system maintains its high performance without requiring complex disassembly.

Dust Drawers with Access from Booth Side

For further convenience, dust collection drawers are placed strategically for easy access from the booth side. This allows operators to quickly and safely remove accumulated dust without needing to disrupt other parts of the system. It simplifies the disposal process, making it both ergonomic and efficient, reducing the physical strain on the operators.

Pulse Controls with Magnahelic Gauge in NEMA 12 Cabinet

The system includes advanced pulse controls for automated cleaning of filters, which improves overall system efficiency and prolongs filter life. The Magnahelic gauge provides real-time feedback on the system's differential pressure, enabling operators to monitor filter conditions and determine when cleaning is needed. The controls and gauge are housed in a NEMA 12-rated cabinet, which offers protection against dust, dirt, and moisture, ensuring the control panel remains fully operational in harsh environments.

More Features

Filters Installed Via Dual-Rail “Single-Push” CAM-Locking Assemblies

The vertically mounted filters are installed using a dual-rail system, allowing for easy filter insertion and removal. The "single-push" CAM-locking assemblies provide a secure and simple way to lock filters into place. This feature allows for faster maintenance, as filters can be changed out quickly without requiring tools or complex procedures, improving operational uptime.

NANO Web, Fire Retardant – MERV-15 Filters

The dust collection system utilizes NANO Web technology in its MERV-15 rated filters. These filters are highly efficient, capable of capturing fine particles and dust while also offering a fire-retardant layer for enhanced safety in potentially hazardous environments. The MERV-15 rating ensures high filtration efficiency, capturing particles as small as 0.3 microns, providing cleaner air and a safer workspace.

Various Power Options Available: 208, 230, 460, and 575 Volts

This dust collection system is compatible with various power configurations, allowing for flexible installation across different industrial settings. Whether your facility operates on 208, 230, 460, or even 575 volts, the system can be configured to meet your power requirements, ensuring seamless integration into existing setups.

Intercept EWC Popular Options

CONTACT US - We will be happy to answer all of your questions!