Economical Cartridge Collector

Economical Cartridge Collector

The economical Intercept™ PKG Series vertical cartridge dust collector can capture and remove most industrial process dust. A packaged dust collector with pre-selected integral fan assemblies commonly used in a variety of applications. A unique CAM-LOC cartridge locking mechanism securely seals the cartridge header plate to the tube sheet to prevent dust bypass. The PKG Series offers standard performance specifications that are suitable for many applications.

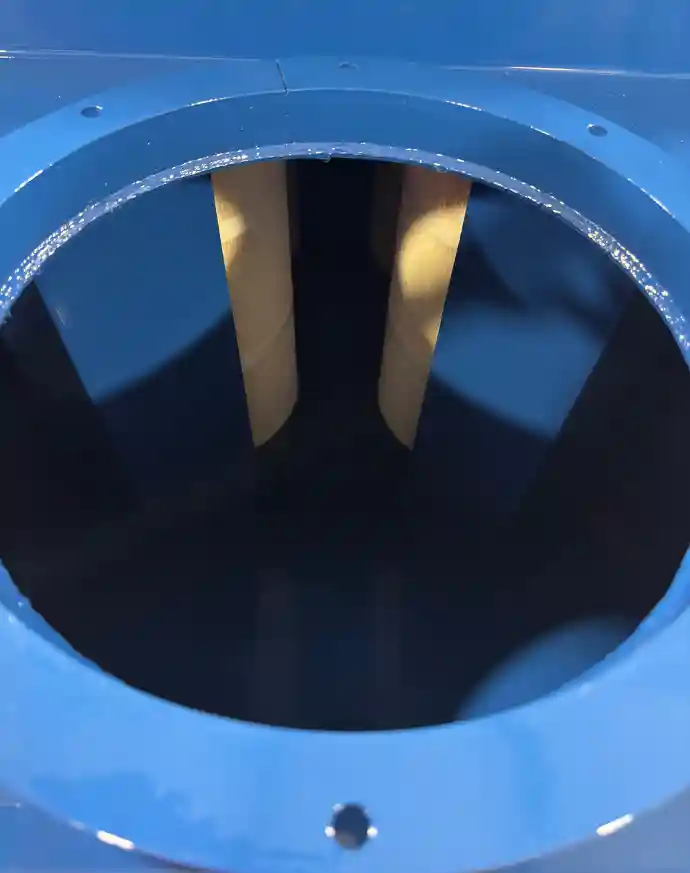

CAM-LOC filter seal

The CAM-LOC filter seal creates an air tight fit against the tube sheet removing the possibility of air leaking around the filter. The release and seal arms make changing filters simple and quick.

The CAM-LOC filter seal creates an air tight fit against the tube sheet removing the possibility of air leaking around the filter. The release and seal arms make changing filters simple and quick.

Standard Performance Configurations

Ranging from 1,500 CFM to 4,500 CFM the Intercept PKG gives you the performance you need for small to medium applications. NANO Web MERV 15 filters provide high efficiency and quick release of particulate when pulsed by the timed pulse controller.

Reverse Pulse Filter Cleaning

Compressed air is forced down into the clean side of the filters blowing built-up dust off the outside of the filters and down into the collection bin. Reverse pulse filter cleaning will extend the life of your filters significantly and create reliable airflow through the ductwork.

ProVent, A Name You Can Trust

We have been manufacturing and improving designs of our dust collectors for over 50 years. A dust collector with the ProVent name will surpass expectations in performance and build quality.

Intercept PKG Popular Options

CONTACT US - We will be happy to answer all of your questions!