Down Draft Wet Dust Collector

The most efficient wet downdraft benches on the market, the Uni-Wash series of wet downdraft tables are capable of collecting dust down to 3 micron in size utilizing only 3″ wg.

Wet type dust collection is required for the safe collection of combustible metal dust. Wet Type Dust Collection has also been used effectively in many other difficult applications in place of cartridge collectors. Our unique scrub design has been an industry standard for over 50 years and continues to lead the industry in Wet Type Dust Collection efficiency.

Low-Cost Operation

Using water as a filtration medium has its advantages for our DDB series dust collector. Collected dust resides as a sludge in the bottom of the sump for easy removal or can simply be drained away. There are no disposable filters to replace saving money and air borne contamination hazard. Our scrub design also leads to a lower static pressure requirement in the machine, which means less horsepower is required. This lowers the cost of the machine and saves energy over the life of the machine.

High Efficiency Motors

We use plug fans for our DDB Series, because the required static pressure is low. This in turn saves money on the machine cost. We use high efficiency direct drive motors to lower operating costs over the lifetime of the equipment.

ProVent, A Name You Can Trust

The Uni-Wash DDB series wet dust collector has been continuously manufactured for over 50 years and continues to be the leading technology for capturing dust without the added cost of cloth filter media. Initially designed for the safe collection of combustible metal dusts, manufacturers have utilized this technology in many other difficult applications with success in more recent years.

Orifice / Impingement Scrub

The large diameter, patented scrub cone assembly inside our DDB series dust collector works above the water line. This orifice/impingement design never clogs or loses airflow as with submerged internal venturi designs which gum-up and impede flow over time. There are no pumps or spray nozzles to clog or fail with the Uni-Wash design.

Uni-Wash DDB Popular Options

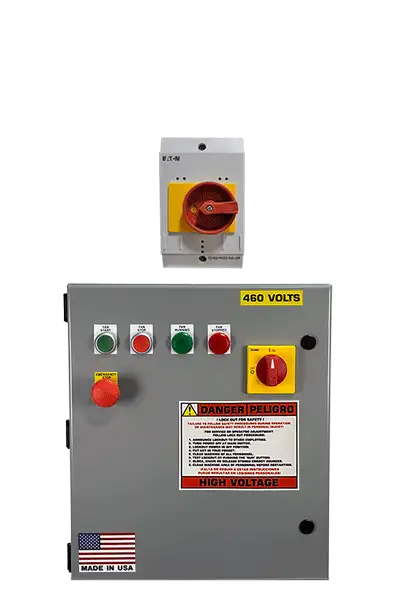

We offer four control options for all Uni-Wash products. We are also a UL 508A certified panel shop, and all panels are manufactured to work seamlessly with our dust collectors.

Base Control Options

Low-cost options where advanced features are not needed. These are an excellent option for down draft benches, because they typically run at full speed.- Across the Line Motor Starter

- Not NFPA 660 Compliant

- NEMA 3R/4/12 Plastic Enclosure

- Float Water Level Control

- Sludge Conveyor Operation via VFD

- Motor Control via Rotary Knob

- Combination Motor Control

- Not NFPA 660 Compliant

- NEMA 3R/4/12 Enclosure

- Float Water Level Control

- Face Mounted Rotary Disconnect

- E-Stop

- 110 Volt AC Components

- Indicator Lights for motor status

- Remote Start / Stop Optional

- Sludge Conveyor Operation via VFD

Our feature rich control panel with touchscreen controls.

Our feature rich control panel with touchscreen controls.

- Fully NFPA 660 Compliant

- NEMA 3R/4/12 Enclosure

- 7-inch Touchscreen

- Provides visual real-time data, control of dust collector and optional components (Auto drain-refill, fault acknowledgement and reset)

- Ultrasonic Water Level Control

- Face Mounted Rotary Disconnect

- E-Stop

- 24 Volt DC Components

- Process Interlock

- Connects power supply to the dust collector to the dust producing equipment

- Stack Light with Audible and Visual Alarms

- Remote Start / Stop Optional

- Sludge Conveyor Operation via VFD

ProVent's premier control panel for Uni-Wash products. The AccuScrub PRO provides optimum efficiency and an easy-to-use 10-inch touchscreen control.

ProVent's premier control panel for Uni-Wash products. The AccuScrub PRO provides optimum efficiency and an easy-to-use 10-inch touchscreen control.

- Fully NFPA 660 Compliant

- NEMA 3R/4/12 Enclosure

- 10-inch Touchscreen

- Provides visual real-time data, control of dust collector and optional components (Auto drain-refill, sludge conveyor, fault acknowledgement and reset)

- Ultrasonic Water Level Control

- Face Mounted Rotary Disconnect

- E-Stop

- 24 Volt DC Components

- Process Interlock

- Connects power supply to the dust collector to the dust producing equipment

- Stack Light with Audible and Visual Alarms

- Remote Start / Stop Ready

- Variable Frequency Drive (VFD)

- Provides manual or automatic control of fan RPM to ensure optimal scrub pressure at maximum efficiency.